Flange Straight-through Throttle Emptying Globe Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

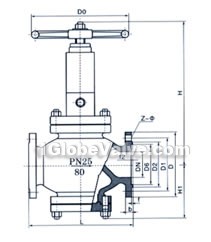

product drawing

Flange straight-through throttle emptying globe valves

Product types:

FJ41.FJL41.CJ41

Product structural features

1.This valve is a new type of throttle, globe, emptying product. It uses cage-shaped throttling, with multi-stage throttling effect, and the throttling effect is evident, sealing is reliable, operation and maintenance is convenient, etc.

2.The valve adopts double sealing (hard, soft sealing), makes the sealing reliably, hard alloy sealing surface can be more resistant to flow erosion, wear-resistant, double sealing can ensure zero leakage under the conditions of the high-pressure gas medium. And the valve service life is long.

3.The seat sealing surface uses conic sealing, it is conducive to self-cleaning the surface dirt attached to the sealing surface.

4.The disc sets a balance hole, piston sealing, ensuring stable operation under open/closed full pressure diffence, open is light and flexible, hoist torque is small.

5.Both throttle emptying globe valve and dual-action thorttle valve have thorttle and cutting off functions(the sealing is zero leakage), the thorttle part is departed from sealing surface, to reduce the flow erosion to the sealing.

6.double-action-type throttle globe valve also has a multi-level throttling, throttle pressure difference is large, and can be applied for throttling and cutting off under high pressure.

7.Packing adopts self-sealing V-shaped packing structure, without regulation, open and off are extremely convenient. Stuffing box has a secondary sealing grease inpouring structure, so that the packing sealing performance is reliable.

8.the valve can be online maintenance, the pipeline can replace the packing and other series easy-demaged parts under normal pressure.

9.A bigger sewage hole has been set at the bottom of the valve, when necessary, open to clean the inner dirt.

Performance and features

1. Normally off state: disc hard sealing press on the seat convex plate, forming a rigid sealing, amd at the same time the soft sealing that embedded in the disc is pressed tightly with seat surface, forming a second sealing, double sealing structure ensures zero leakage, and because the disc has set a balanced hole, it gets smaller force when the valve is open and close, and it also makes the valve with smaller torque when opening and closing.

2. slow pressure status: when the bottom of disc departs from the seat sealing surface, disc and cage-shaped sleeve inner diameter form a sealing because the disc bottom is near to the cage-shaped opening bottom edge. There is no direct venting pressure relief, so achieve a moderating influence.

3.throttle state: the disc bottom leaves the seat, and open further, the small disc forms first level throttle, the high speed liquid flows directly to the opening between the small disc and seat through slow pressure throttle, forming window flow channel, to achieve second level throttle. As the sleeve window edge is thorttle surface, when the high pressure medium washes the throttle channel directly, the bottom of disc produces wortex because of the change of medium direction, mitigating the medium washing directly to the disc, and the seat sealing is also away from the direct washing. Meanwhile because the disc sealing surface is conical, it can purge the dirt and impurities of the seat sealing surface, to protect the sealing surface, thereby extending the valve service life.

4.full-open state: when the disc is in full-open state, the valve is in full venting state, fluid resistance is smaller in the cold part, shortening emptying time and increasing the emptying effect of the valve.

Difunctional thorttle globe valve

Reference standard

API 6D pipe valve specification

GB12235 General Valve flange steel globe and lift check valve

ANSI B16.5a pipe flange and flange components

JB/T79.1-79.2 Whole cast steel pipe flange

GB/T13927 pressure test

JB/T9092 inspection and test

Dimensions & constructral diagram

Flange straight-through throttle emptying globe valve constructral diagram

Main performance and specification

| ASME Pressure Class | normal pressure test(MPa) | suitable temperature°C | applicable medium | |||||||

| sealing | upper sealing | shell | gas sealing | “G” type | “D” type | general type | anti-sulfur type | fundamental type | ||

| nominal pressure PN(MPa) | 1.6 | 1.76 | 1.76 | 2.4 | 0.6 | -29~250 | -46~121 | -29~121 | Containing H 2 S and Co 2 〉500Mg/m 3 medium | oil,natural gas, water,etc |

| 2.5 | 2.75 | 2.75 | 3.75 | 0.6 | ||||||

| 4.0 | 4.4 | 4.4 | 6.0 | 0.6 | ||||||

| 6.4 | 7.04 | 7.04 | 9.6 | 0.6 | ||||||

| 10.0 | 11.0 | 11.0 | 15.0 | 0.6 | ||||||

| 16.0 | 17.6 | 17.6 | 24.0 | 0.6 | ||||||

The materials of main parts

| No. | part name | material | No. | part name | material |

| 1 | double stud | 35CrMo | 14 | bonnet | 25 |

| 2 | nut | 35 | 15 | lower packing gasket | 1Cr13 |

| 3 | bottom cap | 20 | 16 | middle packing | PTFE |

| 4 | O-ring | NBR | 17 | middle packing | NBR |

| 5 | body | WCB | 18 | upper packing gasket | 1Cr13 |

| 6 | seat | 20+ENP | 19 | retainer | PTFE |

| 7 | inner hexagon cylinder head bolt | 35 | 20 | packing gland | 45 |

| 8 | platen | 20 | 21 | support | WCB |

| 9 | sealing ring | NBR | 22 | stem nut | ZQAL9-4 |

| 10 | core sleeve | 20+ENP | 23 | handwheel | 20 |

| 11 | disc | 2Cr13+Ni60 | 24 | nut | 35 |

| 12 | steel ball | Gcr15 | 25 | greasing valve | 25+ galvanization(components) |

| 13 | Stem | 2Cr13 |

Main external dimensions

| PN (MPa) | DN (mm) | dimensions(mm) | weight(kg) | |||

| L | H | H1 | D0 | |||

| 1.6 | 25 | 216 | 243 | 86 | 180 | 17 |

| 40 | 230 | 265 | 108 | 250 | 24 | |

| 50 | 230 | 346 | 115 | 250 | 27 | |

| 80 | 310 | 409 | 146 | 300 | 52 | |

| 100 | 350 | 433 | 163 | 300 | 60 | |

| 150 | 480 | 521 | 202 | 350 | 125 | |

| 200 | 600 | 594 | 292 | 350 | 165 | |

| 250 | 730 | 621 | 355 | 400 | 285 | |

| 2.5 | 25 | 216 | 243 | 86 | 180 | 17 |

| 40 | 230 | 265 | 108 | 250 | 24 | |

| 50 | 230 | 346 | 115 | 250 | 27 | |

| 80 | 310 | 409 | 146 | 300 | 55 | |

| 100 | 350 | 433 | 163 | 300 | 66 | |

| 150 | 480 | 521 | 202 | 350 | 140 | |

| 200 | 600 | 594 | 292 | 350 | 180 | |

| 250 | 730 | 621 | 355 | 400 | 310 | |

| 4.0 | 25 | 216 | 243 | 86 | 180 | 20 |

| 40 | 230 | 265 | 108 | 250 | 29 | |

| 50 | 230 | 346 | 115 | 250 | 32 | |

| 80 | 310 | 409 | 146 | 300 | 67 | |

| 100 | 350 | 433 | 163 | 300 | 80 | |

| 150 | 480 | 521 | 202 | 350 | 168 | |

| 200 | 600 | 594 | 292 | 350 | 215 | |

| 250 | 730 | 621 | 355 | 400 | 372 | |

| PN (MPa) | DN (mm) | dimensions (mm) | weight (kg) | |||

| L | H | H1 | D0 | |||

| 6.4 | 25 | 216 | 243 | 86 | 180 | 20 |

| 40 | 230 | 265 | 108 | 250 | 29 | |

| 50 | 230 | 346 | 115 | 250 | 32 | |

| 80 | 310 | 409 | 146 | 300 | 67 | |

| 100 | 350 | 433 | 163 | 300 | 80 | |

| 150 | 480 | 521 | 202 | 350 | 168 | |

| 200 | 600 | 594 | 292 | 350 | 215 | |

| 250 | 730 | 621 | 355 | 400 | 372 | |

| 10.0 | 25 | 230 | 245 | 78 | 200 | 29 |

| 40 | 260 | 265 | 106 | 250 | 42 | |

| 50 | 300 | 287 | 110 | 300 | 55 | |

| 80 | 380 | 409 | 152 | 350 | 95 | |

| 100 | 430 | 433 | 169 | 350 | 120 | |

| 150 | 559 | 531 | 225 | 400 | 240 | |

| 200 | 660 | 709 | 321 | 500 | 310 | |

| 250 | 787 | 817 | 399 | 500 | 530 | |

| 16.0 | 25 | 230 | 215 | 78 | 200 | 35 |

| 40 | 260 | 265 | 105 | 250 | 50 | |

| 50 | 300 | 237 | 110 | 300 | 65 | |

| 80 | 390 | 414 | 155 | 350 | 116 | |

| 100 | 450 | 440 | 175 | 350 | 145 | |