Electric Flange Straight-through Globe Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

product drawing

Electric flange straight-through globe valves

Structural features

The main structural characteristics of J941 series electric flange straight-throguh globe valve are: 1, exquisite selection, in line with domestic and foreign standards, with reasonable structure, and beautiful shape. 2, the disc and seat sealing surface adopt iron-based alloy or Stellite cobalt-based hard alloy build up welding, with wear-resistance, high temperature resistance, corrosive resistance, good anti-abrasion performance, long service life. 3, after tempering and surface nitriding treatment, the stem has a good anti-corrosion and scratch resistance. 4, it can adopt a variety of pipe flange standards and flange sealing surface pattern, to meet the various project needs and user requirements. 5, full range of body materials, packing, gasket can be selected and matched reasonably according to the actual working conditions or the users’ requests, and it can be applied to all kinds of pressure, temperature and medium conditions. 6, inverted sealing adopts Screw connection sealing seat or body austenitic stainless steel welding, with reliable sealing, and the replacement of packing can be processed in non-stop, convenient and not affect system operation. 7, matching DZW Multi-return electric devices, with a small shell, light weight, comprehensive functions, and can be used with the remote computer accessory, and also can match the electric device according to customers’ requirements. The valve is applied to the pipes of the petroleum, chemical, pharmaceutical, fertilizer, power industry and other working conditions that the nominal pressure is PN1.6 ~ 16MPa, and working temperature is -29 ~ 550 °C, works for cutting off or connecting the pipe medium. Driving modes are manual, gear transmission, electric, pneumatic and so on.

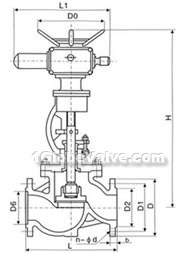

Dimensions & constructral diagram

Electric flange straight-through globe valve constructral diagram

The materials of main parts and main usages

| body/bonnet | disc | sealing ring | Stem | packing | applicable medium | suitable temperature (≤°C) |

| WCB | WCB+D507MO | D577 | 2Crl3 | flexible graphite | water,oil,steam | 425 |

| ZGlCrl8Ni9Ti | 0Crl8Ni9Ti Stellite12 | Stellite6 | lCrl8Ni9Ti | PTFE | nitric acid | 200 |

| ZGlCrl8Ni2Mo2Ti | CF8M Stellite12 | lCrl8Ni2Mo2Ti | lCrl8Ni2Mo2Ti | PTFE | Phosphoric acid, alkali, mixed acid | 200 |

| ZG00Crl7Nil4M02 | CF3M Stellite12 | Stel1ite6 | 316L | PTFE | Phosphoric acid, urea, A ammonium liquid | 200 |

| ZGlCr5MO | ZGlCr5MO Stellite12 | Stel1ite6 | 25Cr2Mo1VA | flexible graphite | water,oil,steam | 550 |

Main external and connection dimenisons

| 1.6MPa | DN | L | D | D1 | b | n-Φd | electric device type | L1 | H | D0 |

| male flange RF J941H J941Y J941W J941F J941N 16C 16P 16R 16I | 50 | 230 | 160 | 125 | 16 | 4-Φ18 | DZW10 | 590 | 645 | 365 |

| 65 | 290 | 180 | 145 | 18 | 4-Φ18 | DZW10 | 590 | 690 | 365 | |

| 80 | 310 | 195 | 160 | 20 | 8-Φ18 | DZW20 | 590 | 715 | 365 | |

| 100 | 350 | 215 | 180 | 20 | 8-Φ18 | DZW20 | 590 | 770 | 365 | |

| 125 | 400 | 245 | 210 | 22 | 8-Φ18 | DZW30 | 590 | 780 | 365 | |

| 150 | 480 | 280 | 240 | 24 | 8-Φ23 | DZW45 | 590 | 875 | 365 | |

| 200 | 600 | 335 | 295 | 26 | 12-Φ23 | DZW60 | 810 | 967 | 470 | |

| 250 | 650 | 405 | 335 | 30 | 12-Φ25 | DZW90 | 810 | 1153 | 470 | |

| 300 | 750 | 460 | 410 | 30 | 12-Φ25 | DZW120 | 830 | 1292 | 550 | |

| 2.5MPa | 50 | 230 | 160 | 125 | 20 | 4-Φ18 | DZW10 | 590 | 645 | 365 |

| male flange RF J941H J941Y J941W 25 25P 25R 25I | 65 | 290 | 180 | 145 | 22 | 8-Φ18 | DZW10 | 290 | 690 | 365 |

| 80 | 310 | 195 | 160 | 22 | 8-Φ18 | DZW20 | 590 | 715 | 365 | |

| 100 | 350 | 230 | 190 | 24 | 8-Φ23 | DZW20 | 590 | 770 | 365 | |

| 125 | 400 | 270 | 220 | 28 | 8-Φ25 | DZW30 | 590 | 780 | 365 | |

| 150 | 480 | 300 | 250 | 30 | 8-Φ25 | DZW45 | 810 | 875 | 470 | |

| 200 | 600 | 360 | 310 | 34 | 12-Φ25 | DZW60 | 810 | 967 | 470 | |

| 250 | 650 | 425 | 370 | 36 | 12-Φ30 | DZW90 | 830 | 1153 | 550 | |

| 300 | 750 | 485 | 430 | 40 | 12-Φ30 | DZW120 | 830 | 1292 | 550 |

| 4.0MPa | DN | L | D | D1 | D2 | D6 | b | n-Φd | 电装型号 electric device type | L1 | H | D0 |

| Female and male flange MFM J941H J941Y J941W 40 40P 40R 40I | 50 | 230 | 160 | 125 | 100 | 88 | 20 | 4-Φ18 | ZDW10 | 590 | 645 | 365 |

| 65 | 290 | 180 | 145 | 120 | 110 | 22 | 8-Φ18 | ZDW10 | 590 | 690 | 365 | |

| 80 | 310 | 195 | 160 | 135 | 121 | 22 | 8-Φ18 | ZDW20 | 590 | 715 | 365 | |

| 100 | 350 | 230 | 190 | 160 | 150 | 24 | 8-Φ23 | ZDW30 | 590 | 770 | 365 | |

| 125 | 400 | 270 | 220 | 188 | 176 | 28 | 8-Φ25 | ZDW45 | 810 | 782 | 470 | |

| 150 | 480 | 300 | 250 | 218 | 204 | 30 | 8-Φ25 | ZDW60 | 810 | 875 | 470 | |

| 200 | 600 | 375 | 320 | 282 | 260 | 38 | 12-Φ30 | ZDW90 | 830 | 1160 | 550 | |

| 6.4MPa | 50 | 300 | 175 | 135 | 105 | 88 | 26 | 4-23Φ | ZDW10 | 590 | 710 | 365 |

| female and male flange MFM J941H J941Y J941W 64 64P 64R 64I | 65 | 340 | 200 | 160 | 130 | 110 | 28 | 8-Φ23 | ZDW20 | 590 | 750 | 365 |

| 80 | 380 | 210 | 170 | 140 | 121 | 30 | 8-Φ23 | ZDW30 | 590 | 785 | 365 | |

| 100 | 430 | 250 | 200 | 168 | 150 | 32 | 8-Φ25 | ZDW45 | 810 | 837 | 470 | |

| 125 | 500 | 295 | 240 | 202 | 176 | 36 | 8-Φ30 | ZDW60 | 810 | 1031 | 470 | |

| 150 | 550 | 340 | 280 | 240 | 204 | 38 | 8-Φ34 | ZDW90 | 830 | 1066 | 550 | |

| 200 | 650 | 405 | 345 | 300 | 260 | 44 | 12-Φ34 | ZDW120 | 830 | 1213 | 550 |