Manual Welding High Temperature and Pressure Globe Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

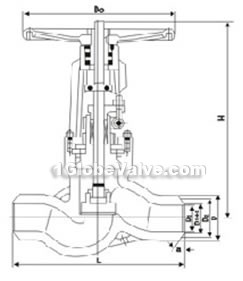

product drawing

Manual welding high temperature and pressure power station globe valves

product usages

J61Y welding straight-through pound class high temperature and pressure power station globe valves is suitable for the pipelines of ANSI Class1500 ~ 3500Lb, working temperature -29 ~ 570 °C oil, chemical, fire station and other working conditions, used as cutting off or connecting media. Applicable medium: water, steam and so on. operation modes are: manual, gear transmission, electric and so on.

Product structural features

1. Product design and manufacture according to ANSI B16.34, E101 standards, can be equipped with imported equipment.

2. Middle cavity uses pressure self-tight sealing structure, the higher the pressure in cavity, the better the performance is. Disc and seat sealing surface uses Stellite cobalt-based hard alloy welding. The depth of the bonnet stuffing box is reasonable, packing plus inhibitor, sealing is reliable, open and close is stable.

3. The valve has upper sealing structure to ensure that there is no leakage through the stem when the valve is running.

4. The open and closure of the valve is controlled by the electrical device, electric devices are equipped with a special motor, reducer, torque control mechanism, on-site operating mechanism, hand, electric switching mechanism. In addition to local operations, it can also carry out long-distance operation.

Dimensions & constructral diagram

Manual welding high temperature and pressure power station globe valve constructral diagram

Main performance and applicable scope

| product type | nominal pressure PN/MPa | test pressure/MPa | working pressure/Mpa | working temperature/°C | applicable medium | |||

| shell intensity | sealing | P54 | P55 | P57 | ||||

| J61H/Y-100 | 10 | 15 | 11 | / | / | / | ≤450 | water,steam,oil |

| J61H/Y-200 | 20 | 30 | 22 | / | / | / | ||

| J61H/Y-250 | 25 | 38 | 28 | / | / | / | ||

| J61H/Y-320 | 32 | 48 | 36 | / | / | / | ||

| J61Y-P54/100V | / | 30 | 22 | 10 | / | / | ≤540 | |

| J61Y-P54/140V | / | 38 | 28 | 14 | / | / | ||

| J61Y-P54/170V | / | 48 | 36 | 17 | / | / | ||

| J61Y-P55/1OOV | / | 38 | 28 | / | 1O | / | ≤555 | steam |

| J61Y-P55/140V | / | 48 | 36 | / | 14 | / | ||

| J61Y-P55/170V | / | 53 | 39 | / | 17 | / | ||

| J61Y-P57/1OOV | / | 48 | 36 | / | / | 10 | ≤570 | |

| J61Y-P57/140V | / | 55 | 40 | / | / | 14 | ||

| J61Y-P57/170V | / | 60 | 44 | / | / | 17 | ||

The materials of main parts

| part name | body | bonnet | Stem | disc | sealing surface | packing | stem nut | handwheel | fastening piece |

| J61H type J961H type | 25 WCB | 25 WCB | Cr stainless steel Cr-Mo-Al steel nitriding | Cr stainless steel | Cr stainless steel | flexible graphite | Al bronze | malleable cast iron | high-quality carbon steel Cr-Mo steel |

| J61Y type J961Y type | 25 WCB | 25 WCB | Cr stainless steel Cr-Mo-Al steel nitriding | 25 | hard alloy | ||||

| J61Y-P54 type J961Y-P54 type | 12CrlMMoV WC6 | 120r1MMoV WC6 | 20CrlMolVA 38Cr1MoAIA | 120r1MoV | hard alloy | ||||

| J61Y-P55 type J961Y-P55 type | 120r1MMoV WC6 | 120r1MMoV WC6 | 20CrlMolVA 38Cr1MoAIA | 120r1MoV | hard alloy | ||||

| J61Y-P57 type J961Y-P57 type | 12CrlMMoV WC6 | 120r1MMoV WC6 | 20CrlMolVA 38Cr1MoAlA | 120r1MoV | hard alloy |

Main dimensions and weight

| nominal diameter DN | main external and connection dimensions/mm | weight/kg | |||||||

| L | D1 | D2 | D3 | ∝ | H | D0 | |||

| J61Y-100、200、250、320 J61Y-P54/100V、P54/140V、 P54/170V | |||||||||

| 1O | 120 | 12 | 25 | / | 37.5° | 185 | 140 | 2.8 | |

| 15 | 150 | 17 | 36 | / | 37.5° | 247 | 200 | 7.5 | |

| 20 | 135 170 | 22 | 42 | / | 37.5° | 248 | 200 | 9 | |

| 25 | 135 170 | 26 | 42 | / | 37.5° | 248 | 240 | 9,5 | |

| 32 | 170 180 | 31 | 44 | / | 37.5° | 248.5 | 280 | 15 | |

| 40 | 230 | 38 | 60 | / | 37.5° | 440 | 280 | 23 | |

| 50(1) | 250 | 50 | 82 | / | 32° | 450 | 320 | 60 | |

| 50(2) | 320 350 | 50 | 82 | / | 32° | 450 | 320 | 64 | |

| 65 | 370 260 | 69 | 100 | 11O | 32° | 669 | 400 | 74 | |

| 80 | 400 430 470 | 84 | 108 | 130 | 32° | 669 | 450 | 112.5 | |

| 100 | 455 560 | 107 | 144 | 165 | 32° | 755 | 500 | 178.5 | |

| Note:DN50 is two structures | |||||||||

| J61Y—P55/100V、P55/140V、P55/170V J61Y—P57/100V、P57/140V、P57/170V | |||||||||

| 10 | 120 | 12 | 28 | / | 37.5° | 189 | 140 | 3 | |

| 15 | 150 | 17 | 40 | / | 37.5° | 250 | 200 | 9 | |

| 20 | 135 170 | 22 | 46 | / | 37.5° | 252 | 200 | 11 | |

| 25 | 135 170 | 26 | 46 | / | 37.5° | 254 | 240 | 13 | |

| 32 | 170 180 | 31 | 49 | / | 37,5° | 254 | 280 | 17 | |

| 40 | 230 | 38 | 60 | / | 37.5° | 440 | 280 | 23 | |

| 50(1) | 250 | 50 | 90 | / | 32° | 453 | 320 | 68 | |

| 50(2) | 320 350 | 50 | 90 | / | 32° | 455 | 320 | 72 | |

| 65 | 370 260 | 69 | 104 | 110 | 32° | 630 | 400 | 83 | |

| 80 | 400 430 470 | 84 | 11O | 140 | 32° | 672 | 450 | 118 | |

| 100 | 455 560 | 107 | 148 | 170 | 32° | 761 | 500 | 185 | |