Oxygen-specific Globe Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

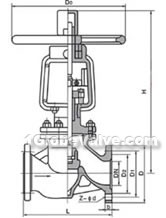

product drawing

Oxygen-specific globe valves(pic1)

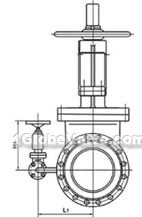

Oxygen-specific globe valve(pic2)

Product introductions

JY41W/Y series of oxygen-specific straight-through globe valve is special valve for oxygen pipelines. According to the operational features of the oxygen pipe network and considering the oxygen medium characteristics of flammable and explosive, using the safe and reliable operation and superior performance as design principles, and refer to the provisions of "Oxygen Safety Regulations" formulated by the Ministry of Metallurgical Industry of China, and then designed and manufactured. It is a special globe valve to ensure the safe operation of oxygen pipe network. The main body uses stainless steel or excellent fire resistant copper alloy, the sealing surface is the body, or welding D802, the rest inner parts are stainless steel or copper alloy; the lubrication of transmission parts uses non-combustible lubricating grease, and marked a clear oil-banned mark. About the structure, the support is all-closed sealing, and has a guided and eliminative static device, the stem matchs with a anti-dust cap. Since it has been running in the market, it has been received good trust by large and medium-sized steel factroies, oxygen plants, petrochemical plants oxygen pipes!

Product structural features

1、For the nominal pressure PN ≥ 1.6MPa, DNl25 ~ 200, using inner bypass structure; and for DN250 ~ 500, using outer structure. The purpose is to reduce the pressure difference before valve and after valve, in order to avoid high flows, high erosion, and prevent the generation of high temperature, thus ensuring the safe operation of the oxygen pipe network, and also reducing the operating torque.

2、The medium flow direction: PN ≥ 1.6MPa, DN ≤ 100 media inflood the upper disc from the bottom of disc (low entering and high out), DN ≥ 125 media inflood the bottom of disx from the upper disc (high entering and low out). The valves that DN ≥ 125 use a high entering and low out flows, one side to meet the structural requirement of inner bypass valve, and on the other side because of the media pressure effect, the closed force is reduced greatly.

3、Oxygen-specific straight-through globe valve has guided static safety devices that can prevent causing sparks because static.

4、Compared with the general globe valve, the support part of the oxygen-specific globe valve uses full sealing structure, and can open the protective cover when pressing packing, playing a role of anti-oil and anti-dust. And it has a clear oil-banned mark.

5、all parts adopt strict degreasing treatment.

Dimensions & constructral diagram

Oxygen-specific globe valve constructral diagram(pic1)

Oxygen-specific globe valve constructral diagram(pic2)

Performance and specification

| nominal pressure(PN) | intensity test pressure(MPa) | gas sealing test pressure(MPa) | applicable medium | suitable temperature |

| water | gas | oxygen | normal temperature | |

| 1.6 | 2.4 | 1.6 | ||

| 2.5 | 3.8 | 2.5 | ||

| 3.0 | 4.5 | 3.0 | ||

| 4.0 | 6.0 | 4.0 |

The materials of main parts

| part name | materials |

| body,bonnet,disc | cast Cr-Ni-Ti stainless steel,copper alloy |

| Stem | Cr-Ni stainless steel |

| stem nut | bronze |

The external and connection dimensions and weight

JY41W-16P JY41Y-16P JY41W-16T| DN | L | D | D1 | D2 | b | f | Z-d | H | H1 | DO | L1 | Weight (kg) |

| 15 | 130 | 95 | 65 | 45 | 14 | 2 | 4-14 | 240 | 100 | 6 | ||

| 20 | 150 | 105 | 75 | 55 | 14 | 2 | 4-14 | 270 | 100 | 8 | ||

| 25 | 160 | 115 | 85 | 65 | 14 | 2 | 4-14 | 270 | 125 | 10 | ||

| 32 | 180 | 135 | 100 | 78 | 16 | 2 | 4-18 | 280 | 160 | 14 | ||

| 40 | 200 | 145 | 110 | 85 | 16 | 3 | 4-18 | 350 | 160 | 20 | ||

| 50 | 230 | 160 | 125 | 100 | 16 | 3 | 4-18 | 400 | 320 | 35 | ||

| 65 | 290 | 180 | 145 | 120 | 18 | 3 | 4-18 | 530 | 360 | 50 | ||

| 80 | 310 | 195 | 160 | 135 | 20 | 3 | 8-18 | 560 | 400 | 65 | ||

| 100 | 350 | 215 | 180 | 155 | 20 | 3 | 8-18 | 618 | 450 | 80 | ||

| 125 | 400 | 245 | 210 | 185 | 99 | 3 | 8-18 | 675 | 450 | 106 | ||

| 150 | 480 | 280 | 240 | 210 | 24 | 3 | 8-23 | 743 | 560 | 125 | ||

| 200 | 600 | 335 | 295 | 265 | 26 | 3 | 12-23 | 850 | 640 | 254 | ||

| 250 | 650 | 405 | 355 | 320 | 30 | 3 | 12-25 | 975 | 270 | 720 | 380 | 418 |

| 300 | 750 | 460 | 410 | 375 | 30 | 4 | 12-25 | 1115 | 270 | 800 | 415 | 502 |

| 400 | 950 | 580 | 525 | 485 | 36 | 4 | 16-30 | 1380 | 280 | 900 | 465 | 980 |

| 450 | 1050 | 640 | 585 | 545 | 40 | 4 | 20-30 | 1530 | 350 | 495 | 1200 | |

| 500 | 1150 | 705 | 650 | 608 | 44 | 4 | 20-34 | 1700 | 400 | 525 | 1300 |

| DN | I | D | D1 | D2 | b | f | Z-d | H | H1 | DO | L1 | Weight (kg) |

| 15 | 130 | 95 | 65 | 45 | 16 | 2 | 4-14 | 240 | 100 | 6 | ||

| 20 | 150 | 105 | 75 | 55 | 16 | 2 | 4—14 | 270 | 100 | 8 | ||

| 25 | 160 | 115 | 85 | 65 | 16 | 2 | 4—14 | 270 | 125 | 10 | ||

| 32 | 180 | 135 | 100 | 78 | 18 | 2 | 4-18 | 280 | 160 | 14 | ||

| 40 | 200 | 145 | 110 | 85 | 18 | 3 | 4-18 | 350 | 160 | 20 | ||

| 50 | 230 | 160 | 125 | 100 | 20 | 3 | 4—18 | 400 | 320 | 35 | ||

| 65 | 290 | 180 | 145 | 120 | 22 | 3 | 8-18 | 530 | 360 | 50 | ||

| 80 | 310 | 195 | 160 | 135 | 99 | 3 | 8-18 | 560 | 400 | 65 | ||

| 100 | 350 | 230 | 190 | 160 | 24 | 3 | 8-23 | 618 | 450 | 88 | ||

| 125 | 400 | 270 | 220 | 188 | 28 | 3 | 8-25 | 675 | 450 | 115 | ||

| 150 | 480 | 300 | 250 | 218 | 30 | 3 | 8—25 | 743 | 560 | 148 | ||

| 200 | 600 | 360 | 310 | 278 | 34 | 3 | 12-25 | 850 | 640 | 293 | ||

| 250 | 650 | 425 | 370 | 332 | 36 | 3 | 12—30 | 975 | 270 | 720 | 380 | 455 |

| 300 | 750 | 485 | 430 | 390 | 40 | 4 | 16-30 | 1115 | 270 | 800 | 415 | 585 |

| 400 | 950 | 610 | 550 | 505 | 48 | 4 | 16-34 | 1380 | 280 | 900 | 465 | 1110 |

| 450 | 1050 | 660 | 600 | 555 | 50 | 4 | 20-34 | 1530 | 350 | 495 | 1350 | |

| 500 | 1150 | 730 | 660 | 610 | 52 | 4 | 20-41 | 1700 | 400 | 525 | 1470 |

| DN | L | D | D1 | D2 | D6 | b | f | f1 | Z-d | H | H1 | DO | L1 | Weight (kg) |

| 15 | 130 | 95 | 65 | 45 | 40 | 16 | 2 | 4 | 4-14 | 240 | 100 | 6 | ||

| 20 | 150 | 105 | 75 | 55 | 5l | 16 | 2 | 4 | 4-14 | 270 | 100 | 8 | ||

| 25 | 160 | 115 | 85 | 65 | 58 | 16 | 2 | 4 | 4-14 | 270 | 125 | 10 | ||

| 32 | 180 | 135 | 100 | 78 | 66 | 18 | 2 | 4 | 4-18 | 280 | 160 | 14 | ||

| 40 | 200 | 145 | 110 | 85 | 76 | 18 | 3 | 4 | 4-18 | 350 | 160 | 20 | ||

| 50 | 230 | 160 | 125 | 100 | 88 | 20 | 3 | 4 | 4-18 | 400 | 320 | 35 | ||

| 65 | 290 | 180 | 145 | 120 | 110 | 22 | 3 | 4 | 8-18 | 530 | 360 | 50 | ||

| 80 | 310 | 195 | 160 | 135 | 121 | 22 | 3 | 4 | 8-18 | 560 | 400 | 65 | ||

| 100 | 350 | 230 | 190 | 160 | 150 | 24 | 3 | 4.5 | 8-23 | 618 | 450 | 88 | ||

| 125 | 400 | 270 | 220 | 188 | 176 | 28 | 3 | 4.5 | 8-25 | 675 | 450 | 115 | ||

| 150 | 480 | 300 | 250 | 218 | 204 | 30 | 3 | 4.5 | 8-25 | 743 | 560 | 148 | ||

| 200 | 600 | 375 | 320 | 282 | 260 | 38 | 3 | 4.5 | 12-30 | 850 | 640 | 293 | ||

| 250 | 650 | 445 | 385 | 345 | 313 | 42 | 3 | 4,5 | 12-34 | 975 | 270 | 720 | 380 | 540 |

| 300 | 750 | 510 | 450 | 408 | 364 | 46 | 4 | 4.5 | 16-34 | 1115 | 270 | 800 | 415 | 770 |

| 400 | 950 | 655 | 585 | 535 | 474 | 58 | 4 | 5 | 16-41 | 1425 | 280 | 900 | 465 | 1330 |

| 450 | 1050 | 680 | 610 | 560 | 524 | 60 | 4 | 5 | 20-41 | 1570 | 350 | 495 | 1550 | |

| 500 | 1150 | 755 | 670 | 612 | 576 | 62 | 4 | 5 | 20-48 | 1740 | 400 | 525 | 1670 |