Globe Valve > Products >UJ41H Flange Straight-through Plunger Globe Valve

UJ41H Flange Straight-through Plunger Globe Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

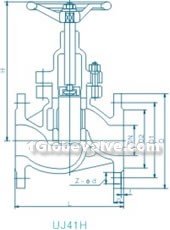

product drawing

UJ41H flange straight-through plunger globe valves

Dimensions & constructral diagram

UJ41H flange straight-through plunger globe valve constructral diagram

Chief property and specification

| Nominal pressure | Shell test pressure | High pressure test pressure | Low pressure test pressure | Applicable medium | Suitable temperature |

| 1.6 | 2.4 | 1.76 | 0.5-0.7 | C water, oil, steam | ≤425°C |

| 2.5 | 3.75 | 2.75 | |||

| 4.0 | 6.0 | 4.4 | P nitric acid | ||

| 6.4 | 9.6 | 7.04 | ≤200°C | ||

| 10.0 | 15.0 | 11.0 | R acetic acid |

Main external and connection dimensions

| diameter | L | H | D | D1 | D2 | b | f | Z-φd | Weight (kg) | |

| mm | inch | |||||||||

| 1.6MPa | ||||||||||

| 15 | 1/2 | 130 | 128 | 95 | 65 | 45 | 14 | 2 | 4-14 | 3 |

| 20 | 3/4 | 150 | 165 | 105 | 75 | 55 | 16 | 2 | 4-14 | 5 |

| 25 | 1 | 160 | 190 | 115 | 85 | 65 | 16 | 2 | 4-14 | 7 |

| 32 | 1 1/4 | 180 | 216 | 135 | 100 | 78 | 18 | 2 | 4-18 | 8 |

| 40 | 1 1/2 | 200 | 236 | 145 | 110 | 85 | 18 | 3 | 4-18 | 12 |

| 50 | 2 | 230 | 250 | 160 | 125 | 100 | 20 | 3 | 4-18 | 16 |

| 65 | 2 1/2 | 290 | 255 | 180 | 145 | 120 | 20 | 3 | 4-18 | 22 |

| 80 | 3 | 310 | 255 | 195 | 160 | 135 | 22 | 3 | 8-18 | 27 |

| 100 | 4 | 350 | 259 | 215 | 180 | 155 | 24 | 3 | 8-18 | 40 |

| 125 | 5 | 400 | 352 | 245 | 210 | 185 | 26 | 3 | 8-18 | 72 |

| 150 | 6 | 480 | 362 | 280 | 240 | 210 | 28 | 3 | 8-23 | 97 |

| 200 | 8 | 600 | 385 | 335 | 295 | 265 | 30 | 3 | 12-23 | 205 |

| 2.5, 4.0MPa | ||||||||||

| 15 | 1/2 | 130 | 133 | 95 | 65 | 45 | 16 | 2 | 4-14 | 4 |

| 20 | 3/4 | 150 | 178 | 105 | 75 | 55 | 16 | 2 | 4-14 | 6 |

| 25 | 1 | 160 | 180 | 115 | 85 | 65 | 16 | 2 | 4-14 | 7 |

| 32 | 1 1/4 | 180 | 195 | 135 | 100 | 78 | 18 | 2 | 4-18 | 10 |

| 40 | 1 1/2 | 200 | 220 | 145 | 110 | 85 | 18 | 3 | 4-18 | 13 |

| 50 | 2 | 230 | 250 | 160 | 125 | 100 | 20 | 3 | 4-18 | 17 |

| 65 | 2 1/2 | 290 | 272 | 180 | 145 | 120 | 22 | 3 | 4-18 | 24 |

| 80 | 3 | 310 | 275 | 195 | 160 | 135 | 22 | 3 | 8-18 | 33 |

| 100 | 4 | 350 | 312 | 230 | 190 | 160 | 24 | 3 | 8-23 | 49 |

| 125 | 5 | 400 | 365 | 270 | 220 | 188 | 28 | 3 | 8-25 | 87 |

| 150 | 6 | 480 | 410 | 300 | 250 | 218 | 30 | 3 | 8-25 | 115 |

| 200 | 8 | 600 | 450 | 360/375 | 310/320 | 278/282 | 34/38 | 3 | 12-25/30 | 210 |

| 6.4MPa | ||||||||||

| 15 | 1/2 | 170 | 145 | 105 | 75 | 55 | 18 | 2 | 4-14 | 5 |

| 20 | 3/4 | 190 | 195 | 125 | 90 | 68 | 20 | 2 | 4-18 | 7 |

| 25 | 1 | 210 | 202 | 135 | 100 | 78 | 22 | 2 | 4-18 | 8 |

| 32 | 1 1/4 | 230 | 226 | 150 | 110 | 82 | 24 | 2 | 4-23 | 12 |

| 40 | 1 1/2 | 260 | 239 | 165 | 125 | 95 | 24 | 3 | 4-23 | 15 |

| 50 | 2 | 300 | 265 | 175 | 135 | 105 | 26 | 3 | 4-23 | 19 |

| 65 | 2 1/2 | 340 | 287 | 200 | 160 | 130 | 28 | 3 | 4-23 | 26 |

| 80 | 3 | 380 | 301 | 210 | 170 | 140 | 30 | 3 | 8-23 | 37 |

| 100 | 4 | 430 | 346 | 250 | 200 | 168 | 32 | 3 | 8-25 | 55 |