Vacuum Isolated Straight-through Globe Valve

manufacturer: Shanghai MeiYan Yi Pump & Valve Co., Ltd.

Eml: sales@1bengfa.com

Tel: +86 (21) 5640 2009

Mob: +86 138 1691 3072(WeChat Same Account)

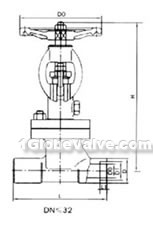

product drawing

Vacuum isolated straight-through globe valves

Product usages

Vacuum isolated straight-through globe valve is applied to nominal pressure PN4.0 ~ 10.0Mpa, operating temperature ≤ 200 °C fire power plant backwater condensate system pipes, worked as cutting off or connecting to the media. Applicable medium: water, steam and so on.

Product structural features

1. The design and manufacture is according to JB/T3595 standard, to meet the requirements of power station equipment matching application.

2. the vacuum sealing structural packing box is designed, with reliable vacuum isolation.

3. after tempering and surface nitriding treatment, the stem has good corrosive resistance and anti-friction performance

4. Flange gasket uses composite materials, with large expansion coefficient, good gas-sealingt performance, ensuring a reliable isolation of system and atmosphere.

5. The inverted sealing adopts stainless steel thread connecting sealing seat or bead welded by austenific stainless steel, and is reliable. The replacement of packing and maintenance can be processed without stopping the operation.

Dimensions & constructral diagram

Vacuum isolated straight-through globe valve constructral diagram(pic1)

Vacuum isolated straight-through globe valve constructral diagram(pic2)

The materials of main parts

| body | 25、WCB | Cr5Mo |

| bonnet | 25、WCB | Cr5Mo |

| support | 25、WCB | Cr5Mo |

| disc | 2Cr13、WCB | Cr5Mo |

| Stem | 2Cr13 | 38CrMoAL、25Cr2MoV |

| seat | 25、304 | 304 |

| sealing ring | expand flexible graphite | |

| packing | expand flexible graphite | |

| stem nut | ZCuA110Fe3 | |

Main performance and specification of NKJ61 type

| product type | Shell intensity test | upper sealing test | sealing test/MPa | applicable medium | suitable temperature/°C |

| NKJ61H-40 | 6.O | 4.4 | 4.4 | water, steam ,air | ≤425 |

| NKJ61H-60 | 9.6 | 7.O | 7.O | ||

| NKJ61H-100 | 15.O | 110 | 11.O | ||

| NKJ61Y-40l | 6.O | 4.4 | 4.4 | water,steam,air | |

| NKJ61Y-64I | 9.6 | 7.0 | 7.0 | ≤550 | |

| NKJ61Y-100I | 15.0 | 11.0 | 11.0 |

The materials of main parts

| part name | body,bonnet | Stem | disc | sealing surface | stem nut | packing | fasten piece |

| NKJ61H-C type | 25 or WCB | Cr stainless steel | Cr stainless steel | H:alloy steel | Al bronze | expand composite graphite | high quality carbon steel |

| NKJ61Y-I type | Cr-Mo steel | 20Cr1Mo1VA or 38Cr1MoAIA | 120r1M0 1VA | Y:hard alloy | Cr-MO steel |

Main dimensions and weight

| nominal diameter DN/mm | nominal pressure DN/mm | main external and connection dimension/mm | |||||||

| L | H手 | D | Do | D1 | L1 | α | W | ||

| 10 | 4.0 | 130 | 245 | 36 | 11 | 18.4 | 10 | 120 | |

| 15 | 130 | 245 | 36 | 16 | 22.5 | 10 | 120 | ||

| 20 | 150 | 265 | 44 | 21 | 28.5 | 11 | 160 | ||

| 25 | 160 | 270 | 48 | 26 | 34.5 | 12 | 200 | ||

| 32 | 180 | 285 | 48 | 34 | 37°30’ | 200 | |||

| 40 | 200 | 320 | 55 | 40 | 37°30’ | 240 | |||

| 50 | 230 | 365 | 64 | 48 | 37°30’ | 320 | |||

| 65 | 290 | 410 | 82 | 66 | 37°30’ | 300 | |||

| 80 | 310 | 430 | 95 | 78 | 37°30’ | 300 | |||

| 100 | 350 | 470 | 117 | 100 | 37°30’ | 350 | |||

| 125 | 400 | 500 | 143 | 126 | 37°30’ | 350 | |||

| 150 | 480 | 533 | 167 | 150 | 37°30’ | 400 | |||

| 10 | 6.4 | 130 | 245 | 36 | 10 | 18.4 | 10 | 120 | |

| 15 | 130 | 245 | 36 | 15 | 22.5 | 10 | 120 | ||

| 20 | 150 | 265 | 44 | 20 | 28.5 | 11 | 160 | ||

| 25 | 160 | 270 | 48 | 25 | 34.5 | 12 | 200 | ||

| 32 | 180 | 280 | 48 | 33 | 37°30’ | 200 | |||

| 40 | 200 | 320 | 55 | 39 | 37°30’ | 240 | |||

| 50 | 230 | 365 | 64 | 48 | 37°30’ | 320 | |||

| 65 | 290 | 410 | 82 | 65 | 37°30’ | 320 | |||

| 80 | 310 | 430 | 95 | 76 | 37°30’ | 360 | |||

| 100 | 350 | 470 | 117 | 98 | 37°30’ | 400 | |||

| 125 | 480 | 500 | 143 | 123 | 37°30’ | 400 | |||

| 150 | 480 | 533 | 167 | 148 | 37°30’ | 500 | |||

| 10 | 10.0 | 130 | 245 | 36 | 10 | 18.4 | 10 | 120 | |

| 15 | 130 | 245 | 36 | 14 | 22.5 | 10 | 120 | ||

| 20 | 150 | 265 | 44 | 20 | 28.5 | 11 | 160 | ||

| 25 | 160 | 270 | 48 | 25 | 34.5 | 12 | 200 | ||

| 32 | 180 | 285 | 48 | 32 | 37°30’ | 200 | |||

| 40 | 200 | 320 | 55 | 38 | 37°30’ | 240 | |||

| 50 | 230 | 355 | 64 | 48 | 37°30’ | 320 | |||

| 65 | 290 | 410 | 82 | 63 | 37°30’ | 320 | |||

| 80 | 310 | 430 | 95 | 74 | 37°30’ | 360 | |||

| 100 | 350 | 470 | 117 | 97 | 37°30’ | 400 | |||

| 125 | 400 | 500 | 143 | 123 | 37°30’ | 400 | |||

| 150 | 480 | 533 | 167 | 148 | 37°30’ | 500 | |||

The materials of main parts

| No. | name | materials |

| 1 | body | WCB, WC6,WC9,C5 CF8,CF8M,CF3,CF3M |

| 2 | disc | 25,1Cr13,2Cr13 1Cr18Ni9Ti, 0Cr18Ni12Mo2Ti 20Cr1Mo1V,25Cr2MoV |

| 3 | eyebbolt | 25,1Cr13,2Cr13 1Cr18Ni9Ti, 0Cr18Ni12Mo2Ti 20Cr1Mo1V,25Cr2MoV |

| 4 | Stem | 25,1Cr13,2Cr13 1Cr18Ni9Ti, 0Cr18Ni12Mo2Ti 20Cr1Mo1V,25Cr2MoV |

| 5 | bellows component | 1Cr18Ni9Ti,304,316,304L,316L |

| 6 | gasket | Flexible graphite and stainless steel, PTFE |

| 7 | bonnet | WCB,WC6,WC9,C5 CF8,CF8M,CF3,CF3M |

| 8 | stud bolt | 0Cr18Ni9Ti, 0Cr18Ni12Mo2Ti 35CrMoV, 25Cr2MoV |

| 9 | hexagon nut | 0Cr18Ni9Ti, 0Cr18Ni12Mo2Ti 35CrMoV, 25Cr2MoV |

| 10 | packing | flexible graphite |

| 11 | packing gland | WCB, WC6, WC9, C5 CF8, CF8M, CF3, CF3M |

| 12 | stem nut | copper alloy |

| 13 | handwheel | WCB、QT400-18 |

Specification and dimensions

| type | GWJ41-16 | ||||||||||||||||||||||||

| pressure class | PN16 | ||||||||||||||||||||||||

| diameter | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | ||||||||||

| L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 | ||||||||||

| H | 190 | 195 | 225 | 260 | 280 | 310 | 340 | 395 | 435 | 470 | 535 | 590 | 630 | 680 | 720 | ||||||||||

| W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 | ||||||||||

| weight(Kg) | 5 | 5 | 5.5 | 11 | 13.5 | 19 | 26 | 36 | 46 | 74 | 102 | 168 | 270 | 420 | 620 | ||||||||||

| GWJ41-25 | |||||||||||||||||||||||||

| pressure class | PN25 | ||||||||||||||||||||||||

| diameter | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | ||||||||||

| L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 | ||||||||||

| H | 190 | 195 | 225 | 260 | 280 | 310 | 340 | 395 | 435 | 470 | 535 | 590 | 630 | 680 | 720 | ||||||||||

| W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 | ||||||||||

| weight(Kg) | 5 | 5 | 5.5 | 11 | 14 | 20 | 27 | 37 | 48 | 77 | 105 | 172 | 3100 | 520 | 690 | ||||||||||

| GWJ41-40 | |||||||||||||||||||||||||

| pressure class | PN40 | ||||||||||||||||||||||||

| diameter | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | ||||||||||

| L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 | ||||||||||

| H | 190 | 195 | 225 | 260 | 280 | 310 | 340 | 395 | 435 | 470 | 535 | 590 | 630 | 680 | 720 | ||||||||||

| W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 340 | 400 | 450 | 450 | 500 | 500 | ||||||||||

| weight(Kg) | 5 | 5 | 5.5 | 11 | 14.5 | 21 | 28 | 39 | 50 | 80 | 108 | 176 | 350 | 590 | 790 | ||||||||||